In a world in full energy transformation, electrification and sustainability have become fundamental pillars for industrial development. The growing demand for solutions that guarantee cleaner and more efficient production has driven companies to innovate in their processes.

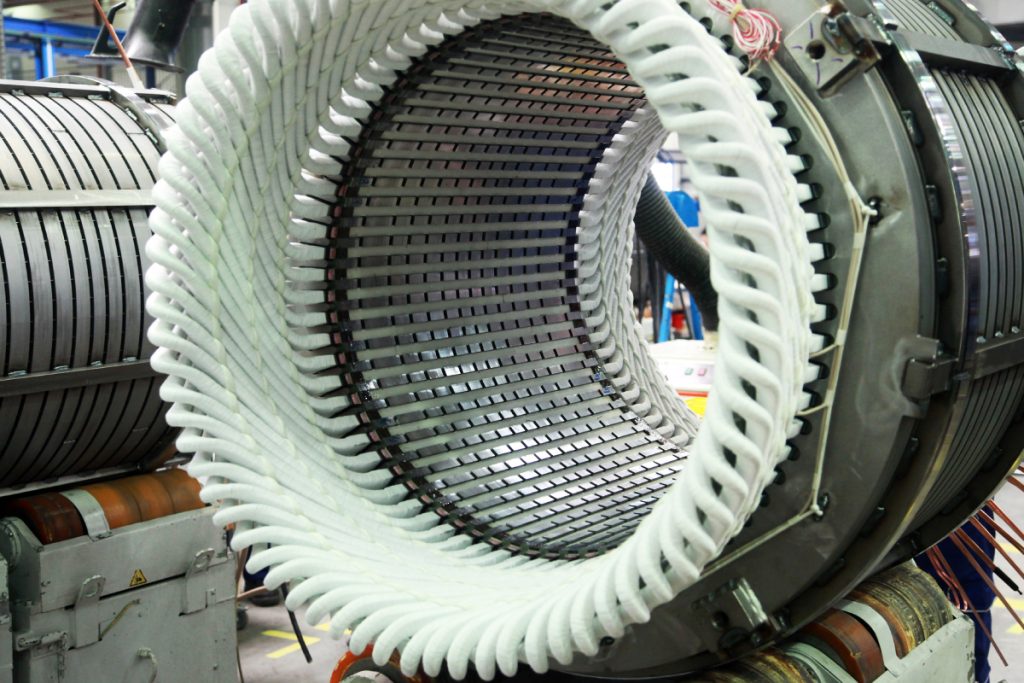

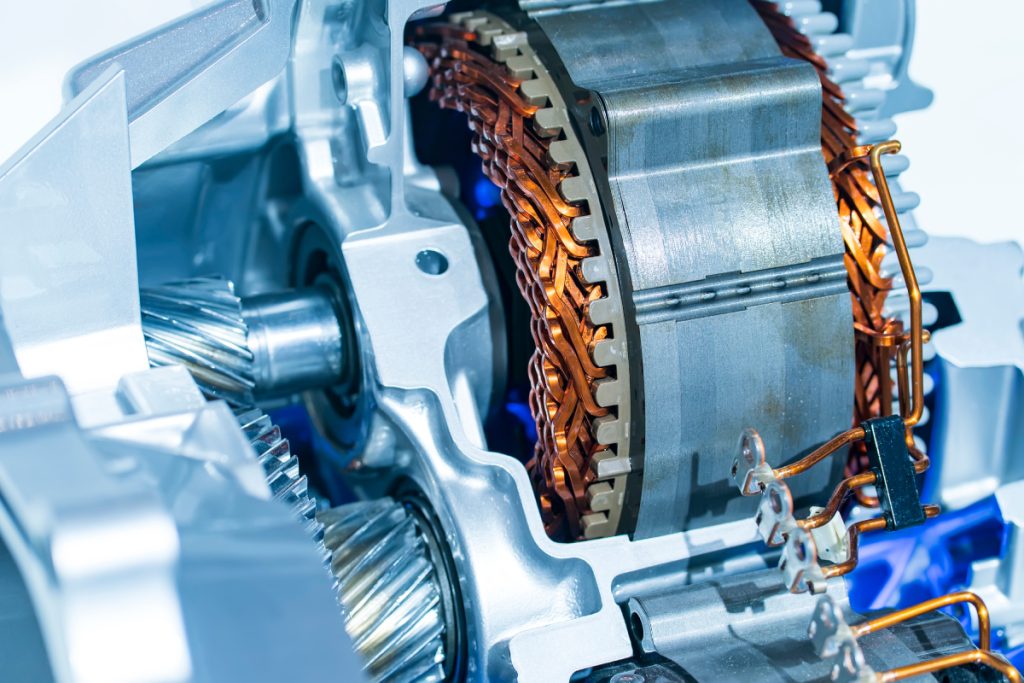

In this context, GH is positioned as a global provider of solutions that contribute to making both challenges a reality across the industries of industrial and EV e-motors, high voltage cables, generators, and transformers using the most efficient and reliable induction heating technology.

The next edition of CoilTech Ausburg in Germany, on March 26 and 27, will be the ideal scenario for professionals and companies to learn first-hand about suppliers and innovations that enable competitiveness in their markets. GH Induction will be at booth 2H16.