In general, the main purpose of annealing heat treatment is to soften the steel, regenerate overheated steel structures or just remove internal tensions.

It basically consists of heating to austenitizing temperature (800ºC and 950ºC depending on the type of steel), followed by slow cooling.

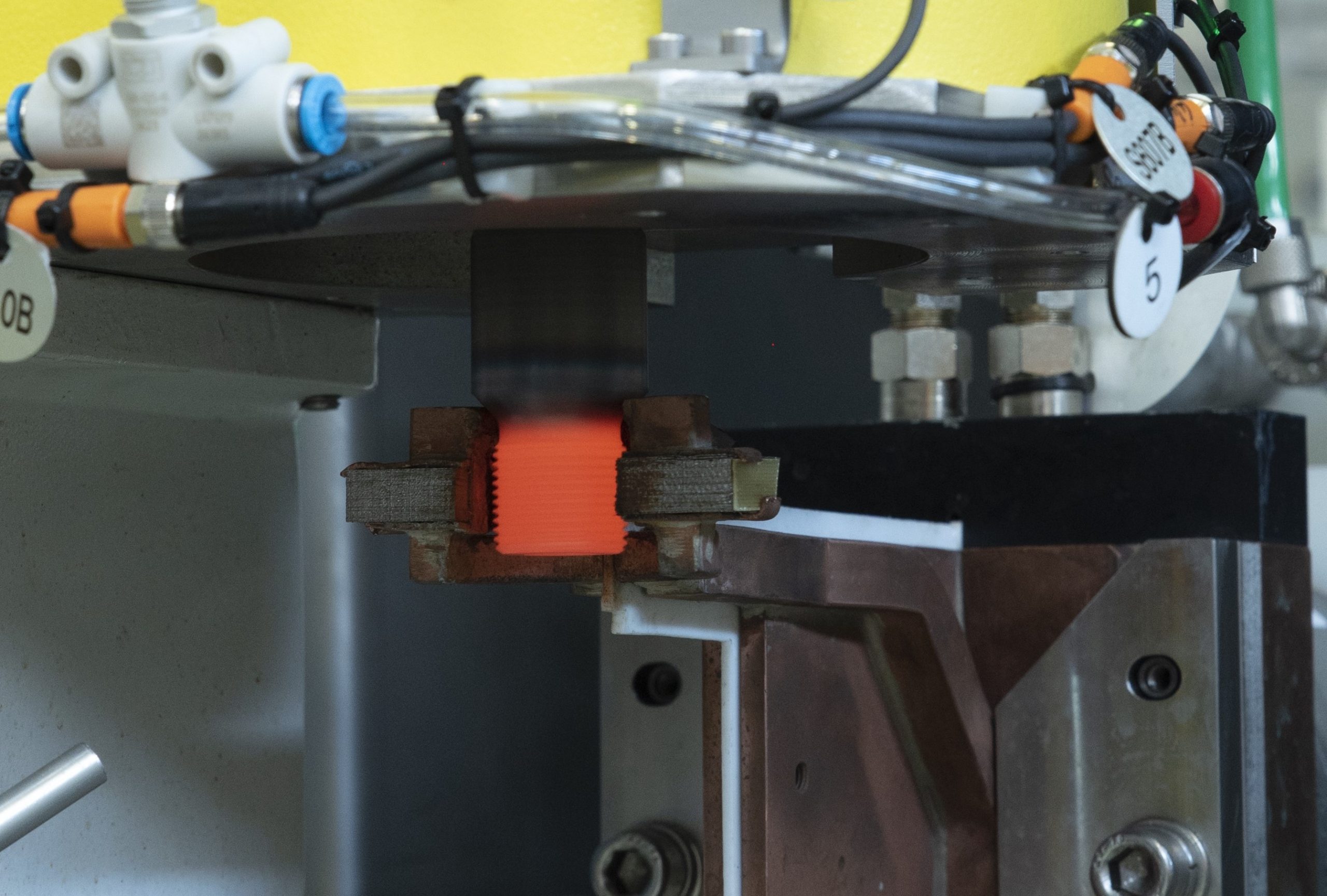

Induction annealing is a highly efficient method that uses electromagnetic fields to achieve precise and localized heating for this process. Induction annealing is significantly faster than traditional furnace-based methods, leading to increased productivity and reduced energy consumption.

Normalization is an annealing process. The objective of normalization is to intend to leave the material in a normal state, in other words with the absence of internal tensions and even distribution of carbon. For the process the high temperatures are maintained until the complete transformation of austenite with air cooling.

It is usually used as a post-treatment to forging, and pre-treatment to hardening and tempering.

Induction is used in most applications of annealing and normalizing in compared to conventional ovens.

Induction annealing of pinions

Induction annealing of pinions