2025-01-29

At GH Induction, we lead the way in induction heating innovation, offering solutions that optimize industrial processes and promote sustainability.

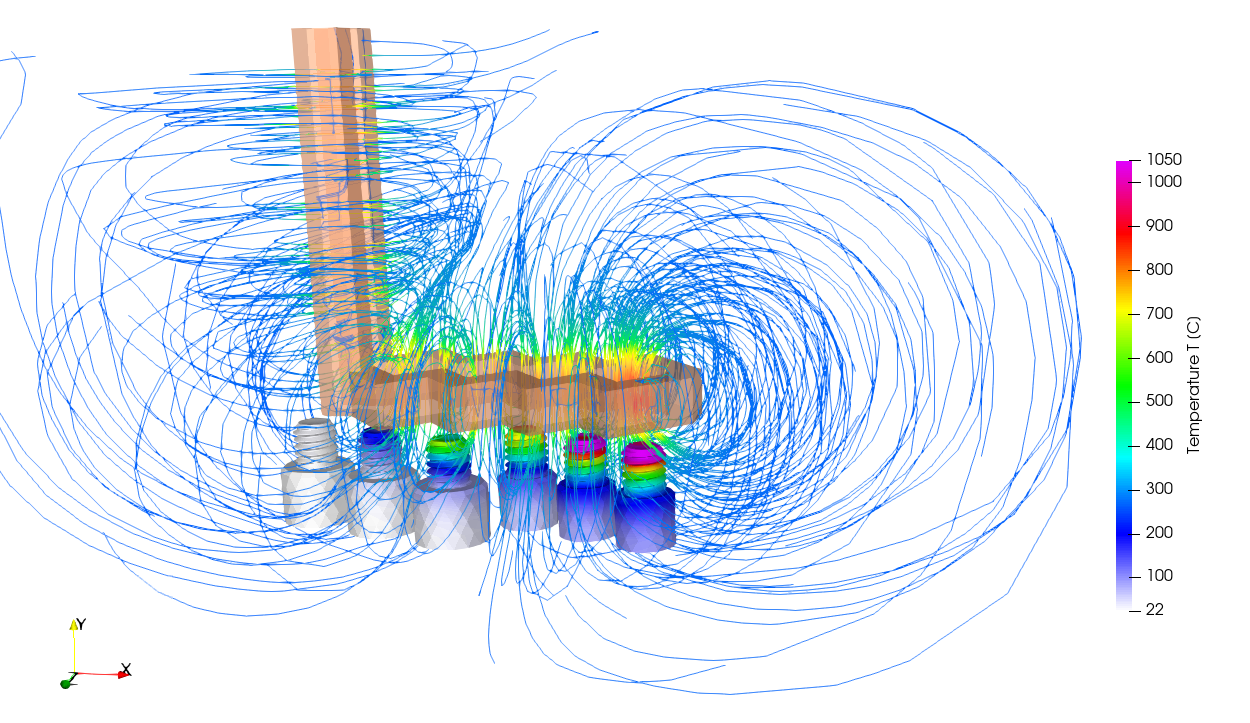

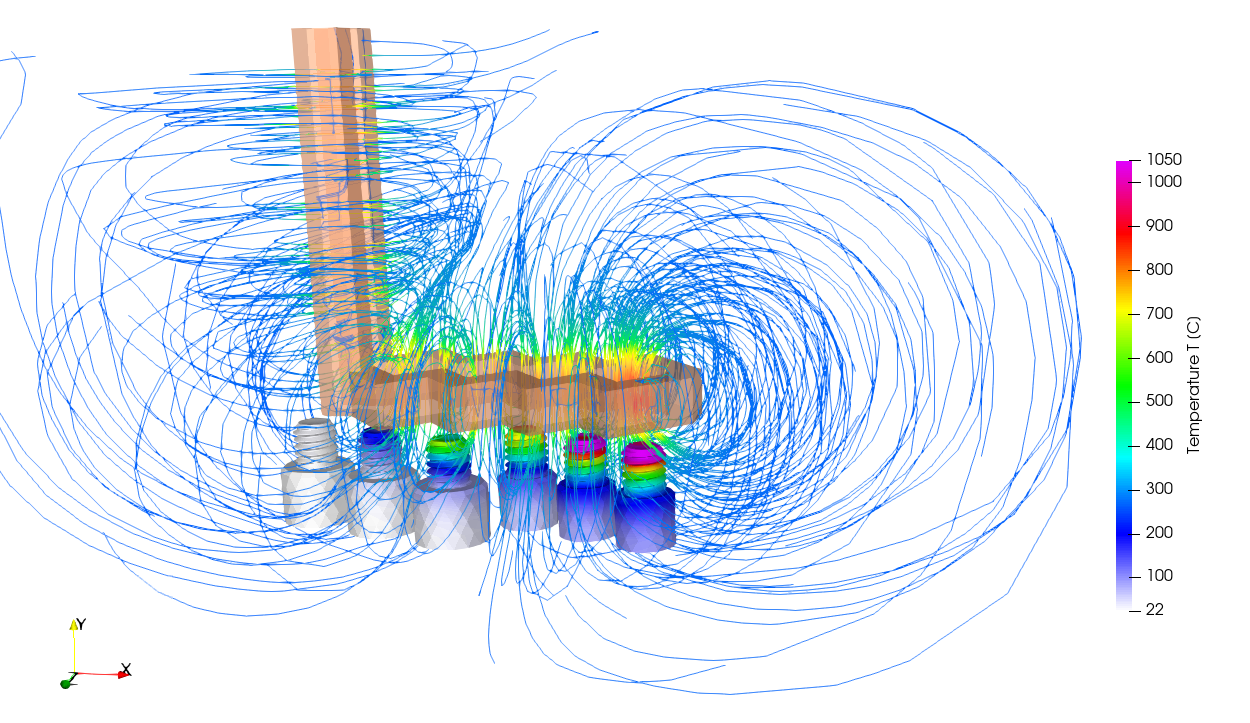

Our advanced technologies reduce energy consumption and CO₂ emissions, contributing to more sustainable and efficient processes. We use Finite Element Method (FEM) simulation to create 3D models of the heating process before conducting real tests with fasteners. This technique allows us to accurately predict how magnetic fields and temperatures interact during quenching, ensuring uniformity and optimal quality. Additionally, FEM simulation facilitates the design of complex inductor geometries, improving process efficiency.

We also employ electron beam melting (EBM) technology to 3D-print pure copper induction coils, eliminating weld points and increasing their durability. This patented process not only extends the lifespan of coils but also enables the design of previously unattainable complex geometries, opening new possibilities for quenching various fastener profiles.

Redefining fastener manufacturing | Fastener + Fixing Magazine was developed as part of our contribution to The Route to Fastener Innovation, an exclusive competition for exhibitors designed to help attendees explore and evaluate the latest innovations in fastening technologies. This initiative, driven by Fastener + Fixing Magazine, takes place at the renowned Fastener Fair Global in Stuttgart (March 25-27, 2025).

Participating in The Route to Fastener Innovation and Fastener Fair Global reinforces our commitment to raising induction heating to excellence standards, benefiting our customers’ manufacturing processes and final product quality.

We thank you for your support on this exciting journey toward the future of the industry!

#GHInduction #TheRouteToFastenerInnovation #FastenerAndFixing #FastenerFairGlobal #IndustrialInnovation #InductionHeating