The easiest way to switch to induction

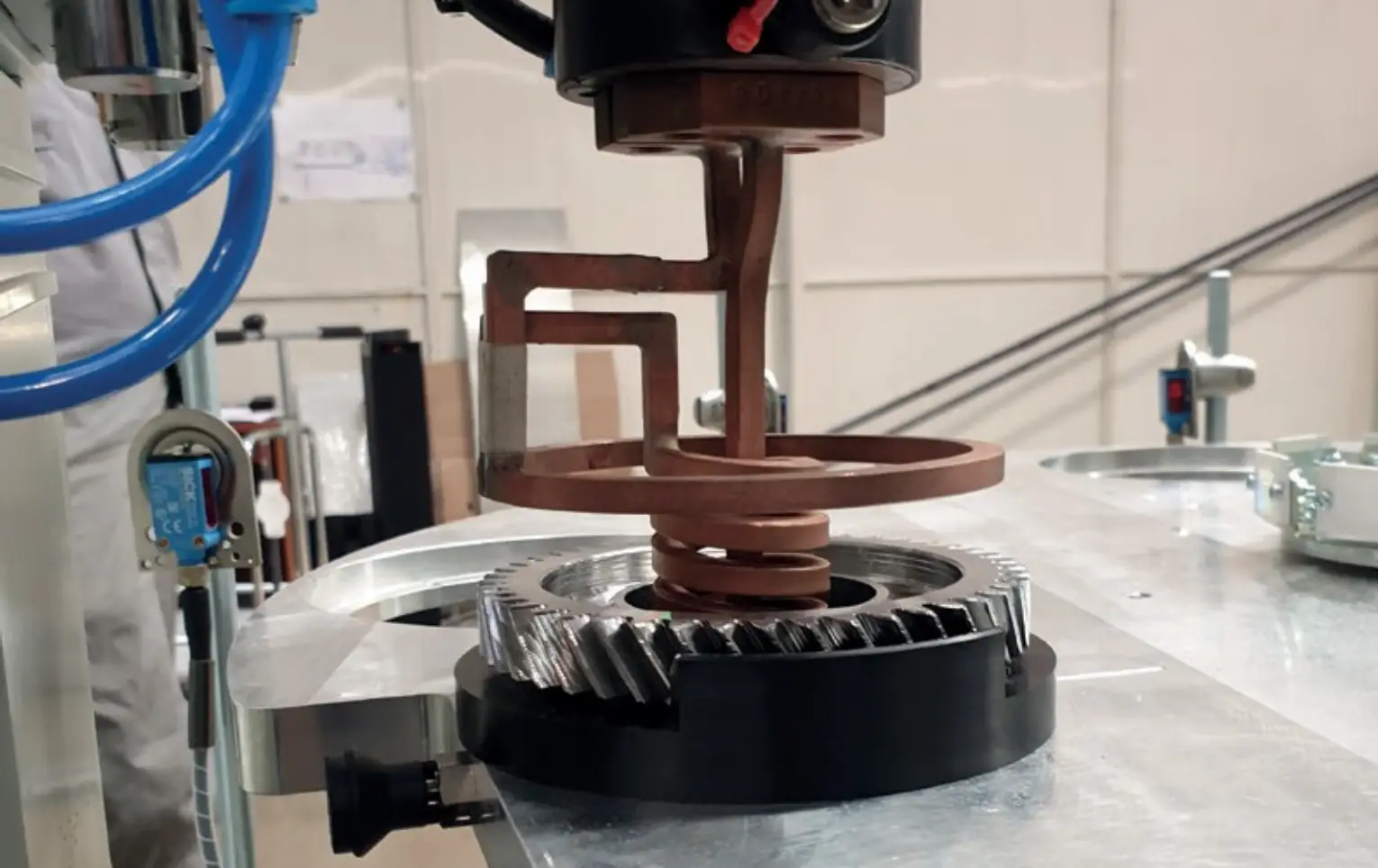

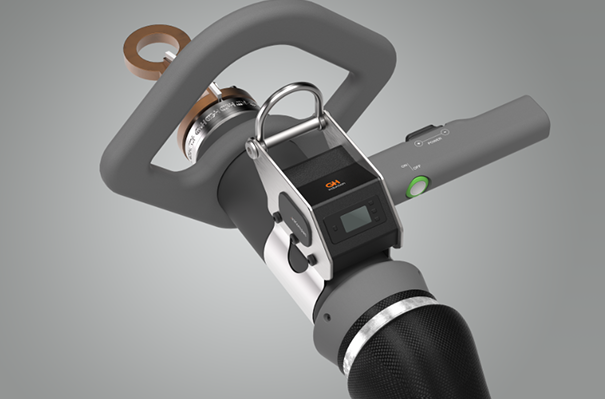

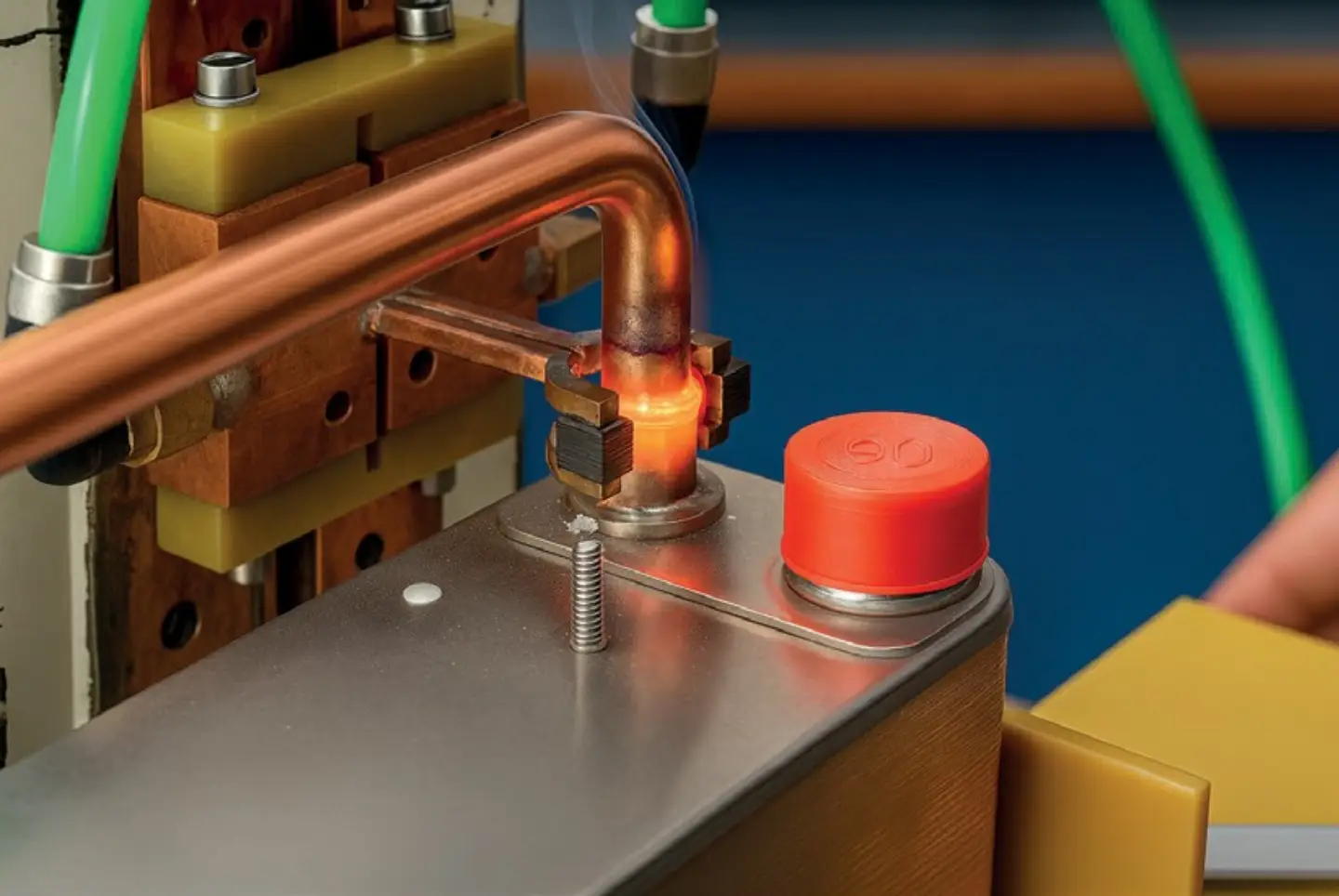

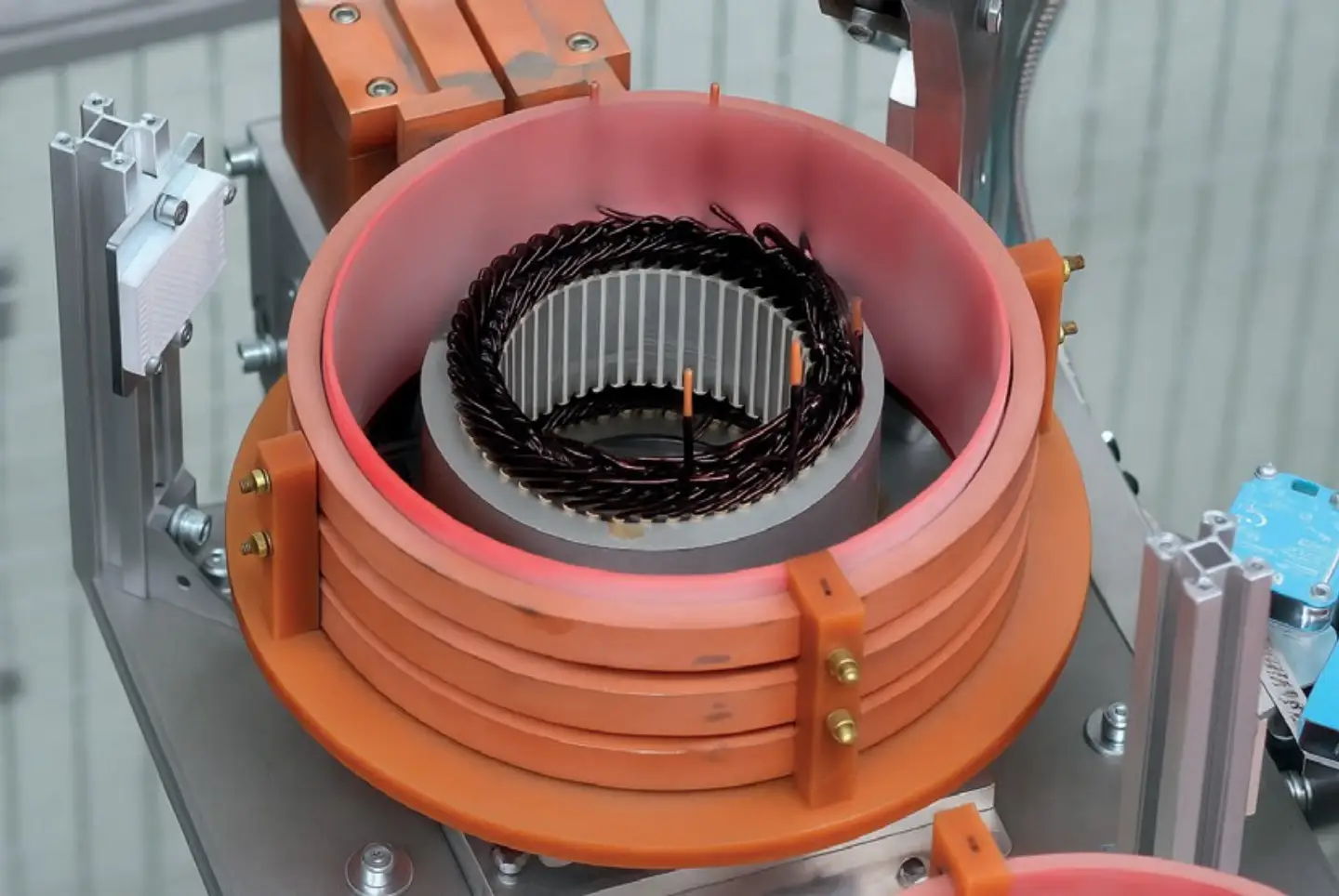

The Essential system is a standardised solution for just one heating station based on the inKompac Essential generator. It is designed for situations where the basics are needed, ensuring efficiency, speed, precision and reliability, without extra costs or complications, with the GH guarantee.

It covers as many medium and high frequency applications as possible with medium-low power ratings, allowing you to adjust your investment and minimise the total cost of ownership of the system.

| IK-E 25MF | IK-E 15MF | IK-E 18HF |

|---|---|---|

| 25kW [10, 25]kHz | 15kW [10, 25]kHz | 18kW [150, 250]kHz |