The customer sells complete cable production lines to final cable manufacturers at a global level. As energy cable sector is an intensive competitive industry, our customer was looking for an improvement in its offer to provide added value to its clients. They wanted to increase the output cable production rate (m/min) reducing bottlenecks in the underground energy cable characterized by a large rubber insulator.

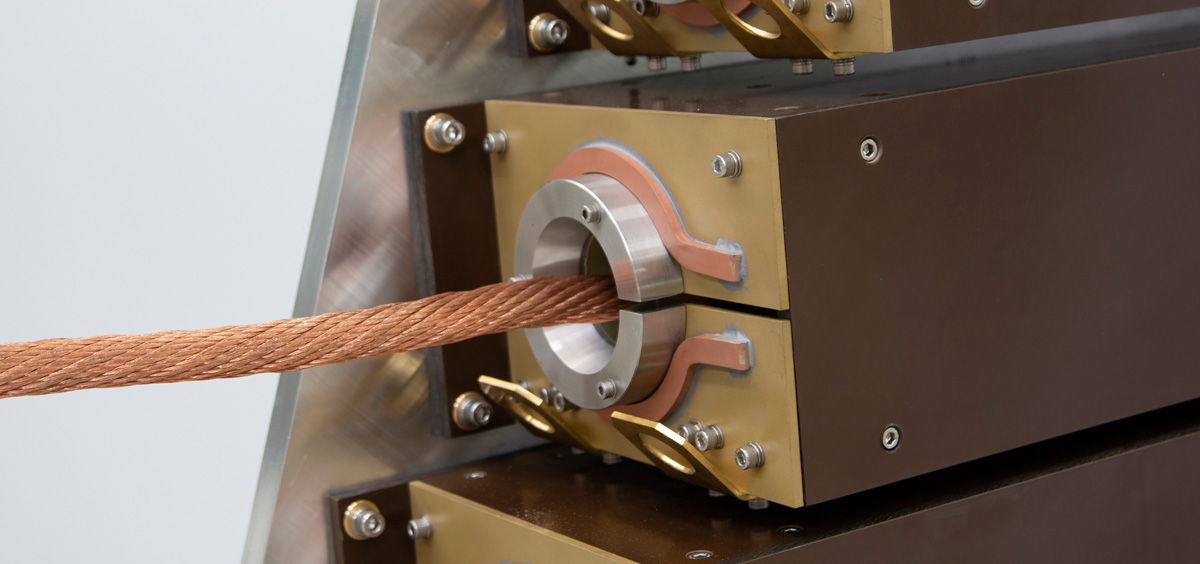

Using a teamwork approach, the customer and GH Group engineers improved the vulcanization process by the replacing resistance heaters with induction heating. The challenge was to integrate the GH solution in the rigid and narrow cable line structure in an aggressive environment with toxic and corrosive fumes.

After a collaborating design period between companies to integrate induction into the cable line and an optimization phase on field tests, GH Group managed a system that improved, up to 10%, the production line performance as main benefit. The higher production in new and existing cable lines became the competitive advantage to keep the customer’s market share.

Currently, GH Group still keeps a continuous improvement commitment with the customer. The original solution has been improved mainly in the O&M part, adding benefits for the customer’s client as low-maintenance design for extended service life.