In modern production, more and more parts are being bonded, replacing various other fastening systems.

In order to achieve fast curing when using reactive adhesives and thus a short cycle time, induction technology is used.

In contrast to an oven or other large-area heating sources, the area to be heated on a component can be very precisely limited to a very small area. The heat is introduced into the workpiece by means of induction and thus also heats the adhesive that is used. The reaction time of the adhesive is considerably shortened by this heat input, and the thermal load on the workpiece is reduced to a minimum.

Our solutions are individually tailored to each application to achieve the best possible results. Concerning the quality of the processing and the finished product, we do not make any compromises, but always strive for perfection.

Our customers therefore often refer to us as “Filigree Manufacture for Inductive Bonding“

The size of the workpieces plays a decisive role if large surfaces are to be heated homogeneously (e.g. plates). Individual areas or circumferential contours are no problem for the induction technology. Here, only the handling or the fixing the workpieces has to be carefully considered.

Heat which is introduced into a workpiece by induction can be very precisely controlled and monitored. In this respect heating is also suitable for complex geometries, especially if they are to be only partially heated. An inhomogeneous mass distribution or areas of the workpiece that are difficult to access have to be specially considered and discussed.

During inductive bonding with the HABIFLEX process the heat treatment of structural and sealing adhesives takes place over the entire circumference of the folding area of parts (doors, engine hoods, etc.) by means of a flexible inductor cable.

In the automotive industry, induction heating is the primary method for curing or preheating adhesives (induction bonding) and sealants (bonding) for closing components such as doors, hoods and trunk lids. However, induction heating processes are also used for the bonding of other body parts such as fenders and mirrors (spot bonding).

They guarantee top quality and high production figures. Due to the use of modern materials these adhesive joints are increasingly needed. Here inductive heating is ideal for the curing (bonding) of adhesives for both bonds with metal as well as with carbon fibers.

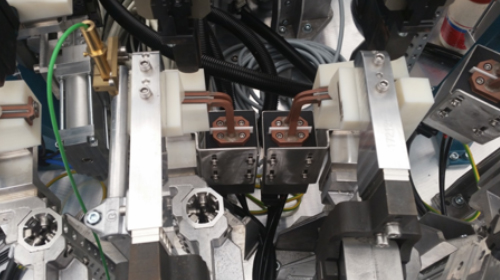

Induction bonding with the hybrid process is a combination of circumferential heating (copper tube) and partial heating (spot).

The circumferential inductor is precisely adapted to the contour of the workpiece and enables preheating the fold edge. This is required to ensure an optimum bond between adhesive and component even when dry lubricants are used. Pre-gelation of the adhesive is achieved by spot heating.

The quantity of spots is determined by the geometry of the component. Several spots can be combined into groups, the regulation and control of which can be carried out individually. In addition, the desired heating profile is generated by adjusting the distance between the inductor and the component.

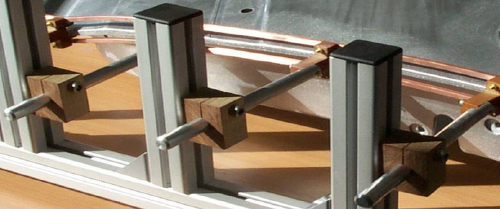

In the process by CIRCULATING INDUCTOR, a copper tube is adapted to the shape of the component. This results in homogeneous heating of structural or sealing adhesives in the rebate area of body add-on parts such as doors or engine hoods.

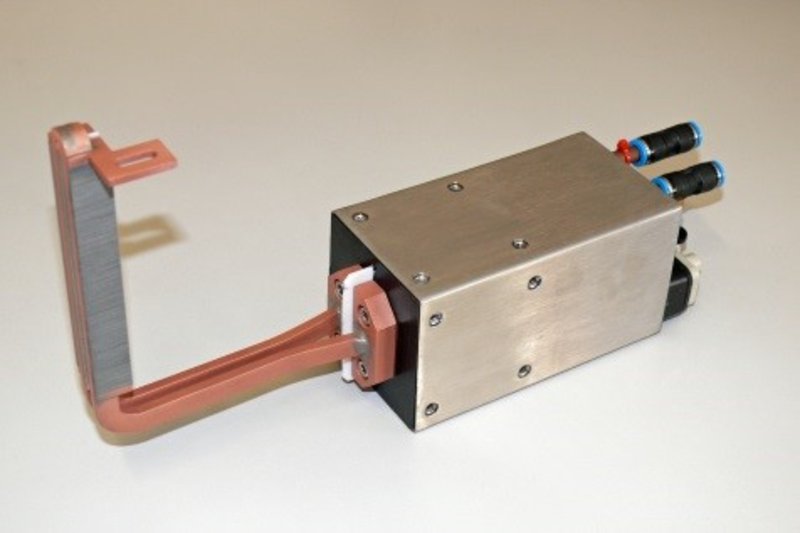

Image: Inductor design made of E-Cu tube, water-cooled.

In induction bonding with the SPOT process, body add-on parts such as doors or engine hoods are partially heated in the fold area. This partial application of heat achieves a reduction in warpage, particularly in aluminum components.

The quantity of spots is determined by the geometry of the component. It is possible to combine several spots into groups, the regulation and control of which can be done individually. In addition, the desired heating profile is generated by adjusting the distance between the inductor and the component.

The prerequisite for inductive bonding is a metallic workpiece or carbon fiber composites. Likewise, two different materials can also be bonded inductively, such as aluminum and steel parts.

The bonding area should be located directly in the effective range of the inductor or in its immediate vicinity in order to exploit the thermal conductivity of the material.

In general, both one-component and two-component adhesives can be inductively gelled.

The limits of induction bonding are primarily determined by the design, geometry or size of the component to be heated. A workpiece that is very inhomogeneous due to its mass distribution can be problematic. Likewise, corners, edges and incisions that are difficult to reach can be classified as critical.

Nothing is impossible, but not everything is feasible.

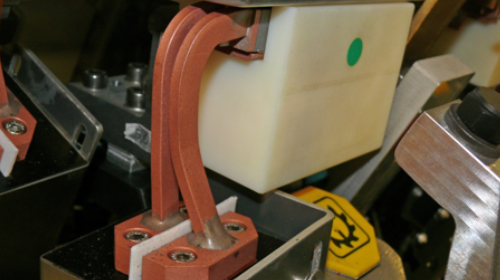

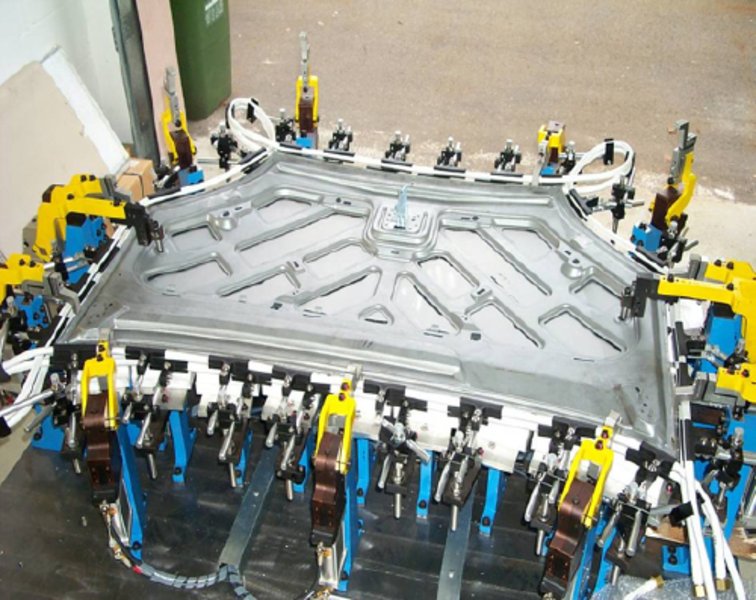

This device is a temperature-resistant component support with pressure pieces and clamps as well as an attached inductor system. The component is held in the correct position and geometry during the gelling/heating process.

Due to the existing holders, fine adjustment of the inductor system is possible. By varying the distance between the inductor system and the component, the temperature distribution can be adjusted according to customer requirements.

Inductor system, specially adapted to the properties of the component.

High-precision supports are needed to gel body add-on parts. These supports, also known as gelation racks or heating stations, are designed and manufactured separately for each add-on part. To bring the part into the desired shape, it is clamped in a defined mold nest and fixed in place by special clamping arms. Finally, clamping units, the type of induction heating and the number of heating points (for spot bonding) ensure that the adhesive is cured.

By cooperating with invenio Automation Solutions GmbH, we combine the expertise of both companies in the field of induction heating: together we create innovative solutions for induction gelling racks – tailored exactly to the customer’s requirements. By adhering to previously defined design guidelines, development and production proceeds according to customer-specific specifications. We supply products of the highest quality, taking into account all applicable regulations, technical standards and norms.

Our partner invenio guarantees the professional development and assembly of the gelling racks. The company can draw on many years of expertise with regard to gelling racks as well as automation, testing technology and system assembly.

With this partnership, which is not based on design and component manufacturing alone, and comprehensive know-how, we guarantee reliable solutions for your add-on parts and the highest quality of inductive gelation racks.

invenio Automation Solutions GmbH, Tiefental 13, 93468 Miltach, Tel. +49 (6142) 899-210, E-Mail: as@invenio.net, https://www.invenio.net/en/

HABIFLEX INDUCTOR CABLE

The HABIFLEX inductor cable is a water-cooled inductor in elastic, flexible tubing form with internal stranded copper wire and screw terminals.

FIXED INDUCTOR

(Copper tube) Circulating water-cooled inductor system made of E-Cu tube, which is adapted to the shape of the component.

SPOT INDUCTOR

The SPOT inductor is a unit consisting of an inductor equipped with field concentrators and a specially designed transformer.

HYBRID INDUCTORS

The HYBRID inductors are a combination of fixed copper tube and spot inductors.

A series-identical component is used for the production of a master component.

This is provided with temperature measuring points by GH. During the measurement with the master component, measuring point temperatures are determined in order to create a temperature curve over a specific heating time. Thus, the master component enables a quality check of the heating process in the production sequence.

The transformer oscillating circuit unit provides the required reactive power for the induction process and is also used for impedance matching of the inductor system to the output voltage of the induction generator of approx. 550V. This impedance matching generates the required currents of approx. 1000A in the inductor system on the secondary side, with the transformer providing galvanic isolation from the power grid. In contrast to a classic mains transformer, the design at 10kHz is significantly reduced in size due to the small core cross-sections and number of windings.

A transistor generator with an operating frequency of 5 – 30 kHz is used for the usual bonding applications. Depending on the application, different power groups of approx. 5 kW…30 kW per power output are used here. With up to 8 power outputs, the available total power can be divided among the individual groups. Each group is independently adjustable and controllable.

The generators are designed to be extremely durable and maintenance-free. The ” glue gel ” process control, equipped with digital signal processing, is an integral part of the induction generator series.

The use of GH induction systems improves equipment operation and maintenance, avoids production downtime, reduces energy consumption, and simplifies and improves part quality control.

Automotive body components

All metal add-on parts such as doors, engine hoods, trunk lids, fenders, etc. can be bonded quickly and with low warpage using induction. Low warpage is ensured by precisely controllable heat input into the workpiece and fixing on a geostation.

Optimum results are made possible by the interaction of a geostation, which is precisely built and measured for each add-on part, and a proven converter with process control. GH has years of experience in this field with several hundred installed units.

Battery bases, accumulators

Batteries and rechargeable batteries play a central role in the field of e-mobility. These batteries are bonded directly or indirectly to the customer’s special superstructures in such a way that both the dissipation of the heat generated during operation and the secure fastening are optimal.

Electric motors

Some electric motor components are inductively heated within the process chain. Typical inductive applications in the field of electric motors are the bonding of magnets in rotors or the gelling process of trickled-on resin in stators.

Electric motors

Electric motors, such as those for vacuum cleaners, are also induction heat treated. The hardening of bonded magnets, even with complex geometries of the workpieces, is the main focus here.