Advising services

These services help to evaluate either the technical and economic feasibility for a new or an improved induction heating process before taking the investment decision.

GH Induction offers the following services either as stand-alone or as part of a turnkey project for facilitating the solution design

Could you improve your business results?

We provide you technical and economical arguments to analyse the viability of investing in an induction heating asset for your production considering the best system configuration.

Do you need to incorporate a new process or to improve an existing one? Is it possible to replace your current heating method by induction technology?

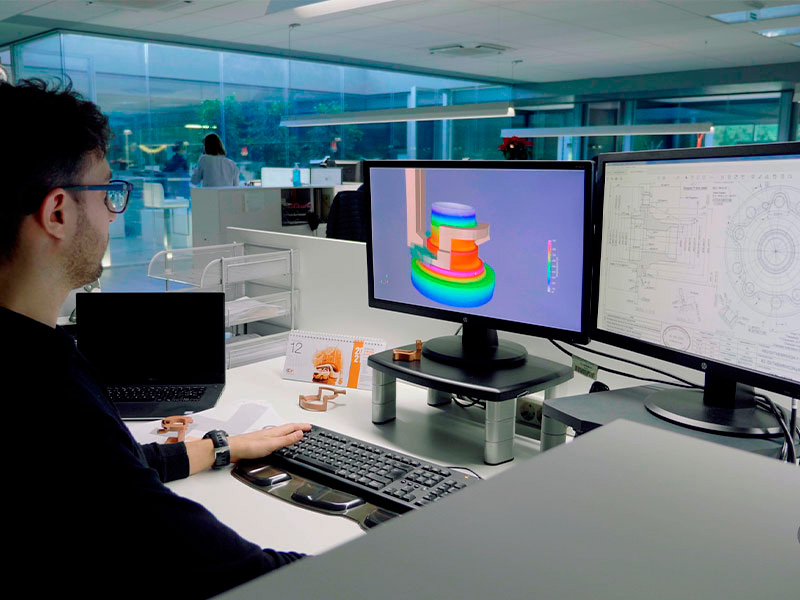

The GH Application engineers are willing to study for developing or optimizing your process under your requirements using tools as computer heating simulation, part test laboratory, metallurgical service, etc.

Do you need to test and to confirm the technical viability of an induction process on your part?

GH Group offers its know-how and a complete laboratory covering a wide range of frequencies and powers to test your new or improved processes.

Do you need a short amount of heated parts before having the final installation on your facilities (for certification, for testing other machine tools, for assembling in your product prototypes or any other purpose)?

Through our inductor manufacturing and part test laboratory we can provide you this service.

It is the 3D inductor manufacturing that allows the best results in an induction process with the shortest possible lead time. It combines two digital technologies and the knowledge and experience of the GH technical team to find the optimal inductor design.