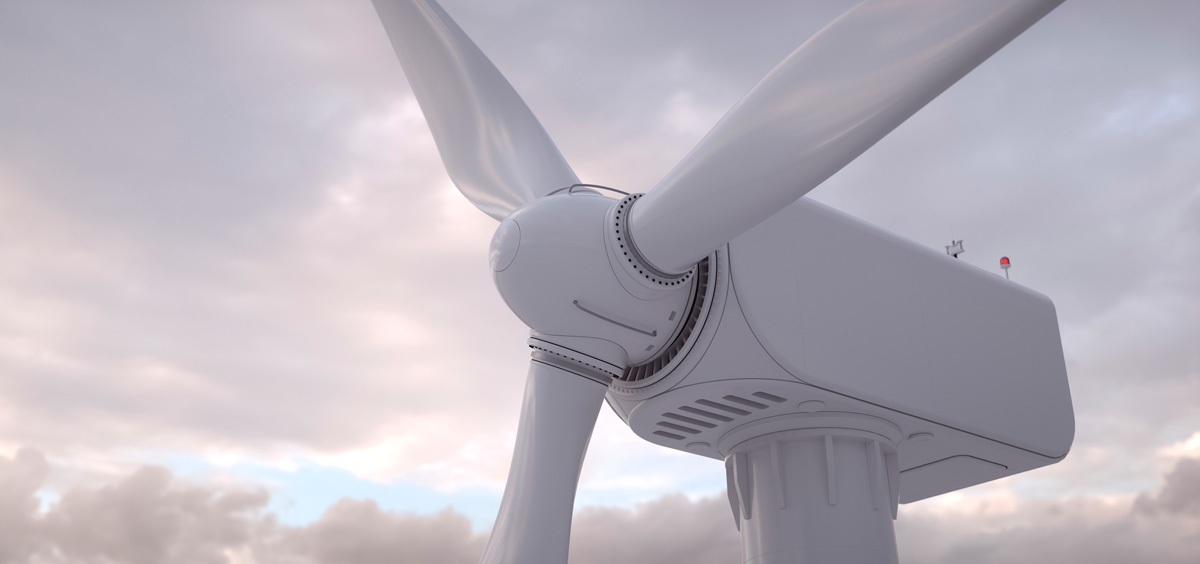

At the beginning of this project, the efficiency of the systems available in the market was inefficient due to the high requirements of adjustment and preparation in the loading of each bearing and during heating. Therefore, the machines needed constant supervision of an expert operator in all the phases of its operation.

The GH solution was compact and free of adjustments. It was based on a lightweight induction system (inductor and transformer) and a set of sensors that provided a data flow allowing recalculation of the process parameters and providing precise location automatically. Thus the GH machine regulated itself automatically without the need of supervision from loading through the end of the hardening cycle, obtaining a faster and more accurate process than previous solutions.

The benefits for the customer were a reduction of the production time and reduction of specialized manpower, generating greater flexibility in the production resources.