Induction heating for automation

Imagine that you can now achieve your goals.

The digital heating

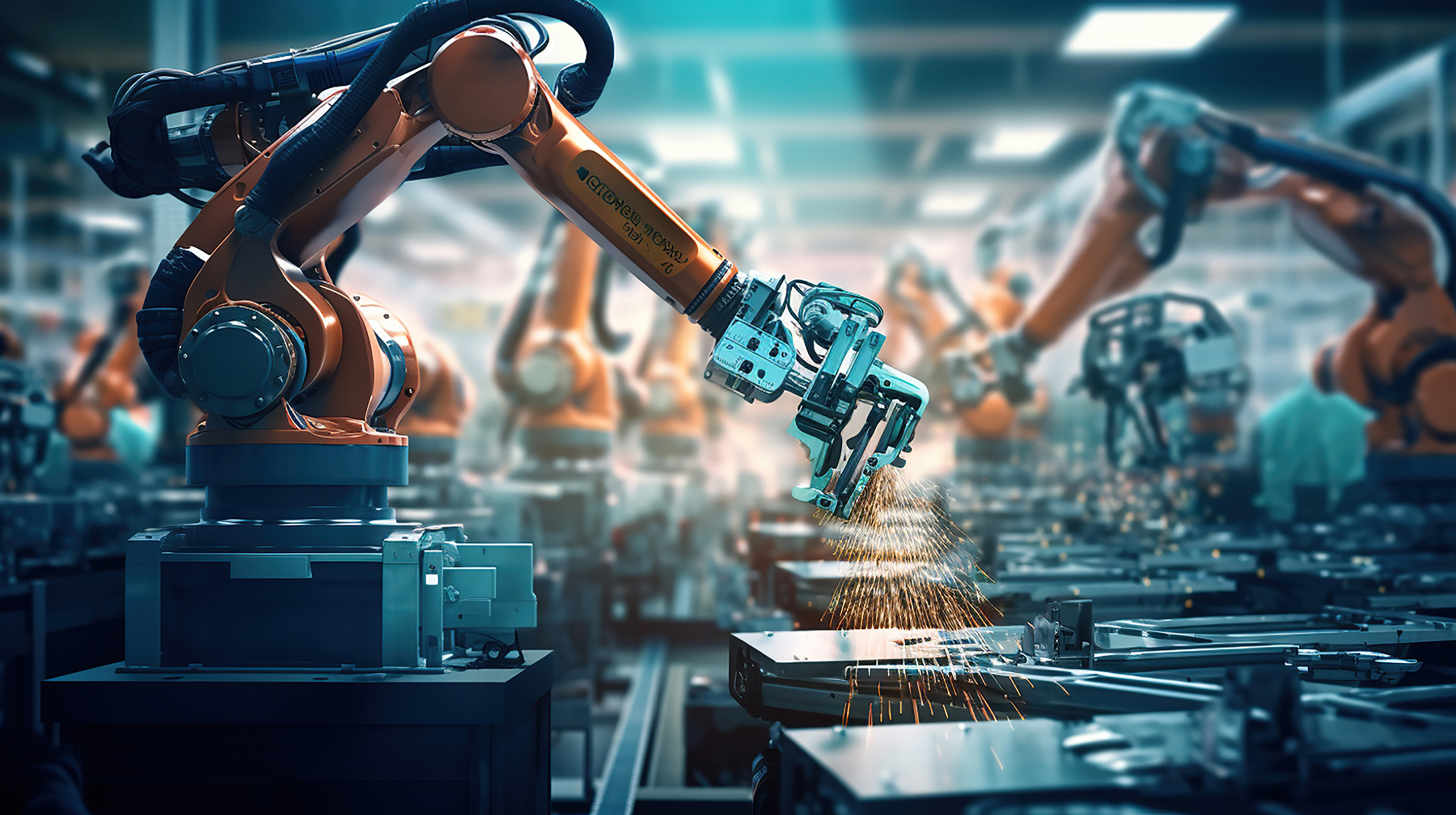

Currently the use of electromagnetic induction is the most suitable heating method to achieve an automated or semiautomated process; and to replace other less efficient processes such as gas torches or heating element systems in the production of parts or components.

An induction heating can be integrated:

Precise temperature control, programming of heating cycles; repeatability and safety and compliance with regulation are some of the advantages of our solutions.

In addition, our innovative AIC system for automated inductor changes drastically reduces changeovers and human errors, thus reducing the investment in induction equipment. If you are interested, ask us how it could be implemented in your case.

Examples of induction heating in automated machines

Induction heating system based on inKompac for an automated brazing machine by robot replacing gas torches

Integration of an induction station into a GH automated machine for hardening using Transithermic power supply

Do you want to integrate induction into your machine?

inKompac is the perfect solution up to 60Kw:

For higher power ratings, the Transithermic family is used.

Increase of productive efficiency, no manual changeovers.

Recommended when manual changeovers are high time-consuming and could imply important stoppages due to human mistakes. Depending on your production requirements and your investment, GH designs and customizes the solution.

Energy efficiency and ruggedness. GH power supplies combine Silicon Carbide (SiC) cutting edge technology with rugged construction for the ultimate in durability and versatility

State-of-the-art Silicon Carbide (SiC) semiconductor materials are used to increase energy efficiency, high power density, bandwidth, and resistance to voltage and temperature.

Production quality and traceability are two of the most important aspects of any manufacturing process. As such, IPM (Induction Process Monitoring) is a mandatory digital system to ensure the quality of the process, comply with ISO/TS 16949 and CQI-9 standards. It is based on a 100% control over the treated parts; and on real-time measurements of the parameters involved in the treatment.