GH Induction launches inKompac Essential

Designed to provide a robust, efficient and economical solution without compromising on quality or reliability, this new model is an essential addition to any industry.

Whatever your industry and whatever size you are, we work with you to create the most efficient induction heating solution for your objective by applying our technology, service, and experience.

We are a group of companies specialised in turnkey projects. From making the application of induction viable in your process, to designing and manufacturing the systems you need.

Always taking care of your investment anywhere in the world.

Which type of project do you need and what for?

If you are wondering how to improve your process with induction heating, tell us your idea and we will help you find out if it is feasible and how to implement it.

When you are looking for a new induction heating machine or equipment for your production.

We will design an offer that meets your objectives without obligation.

Want to save a bit more?

If you want to renew your induction equipment, we’ll study how to extend its performance and useful life.

We can propose options for you.

Even if you are already applying induction heating in your processes, we can help you to improve it.

We will see where you start from and how far you can go.

Inspirational stories of innovative companies that managed to improve their efficiency

More efficient process

We discovered with the customer the feasibility of the induction burning process for copper conductors and improved the efficiency of the process.

ALSTOM

Efficiency with small batches

For a new plant we developed a machine with automatic inductor change.

ITM GROUP

For energy savings

Our technical support and spare parts service enabled the customer to anticipate a possible production interruption.

SANDVIK

Higher production and costs reduction

We improved the inductors service life with 3D additive manufacturing, and collaborative work with the customer.

RENAULT

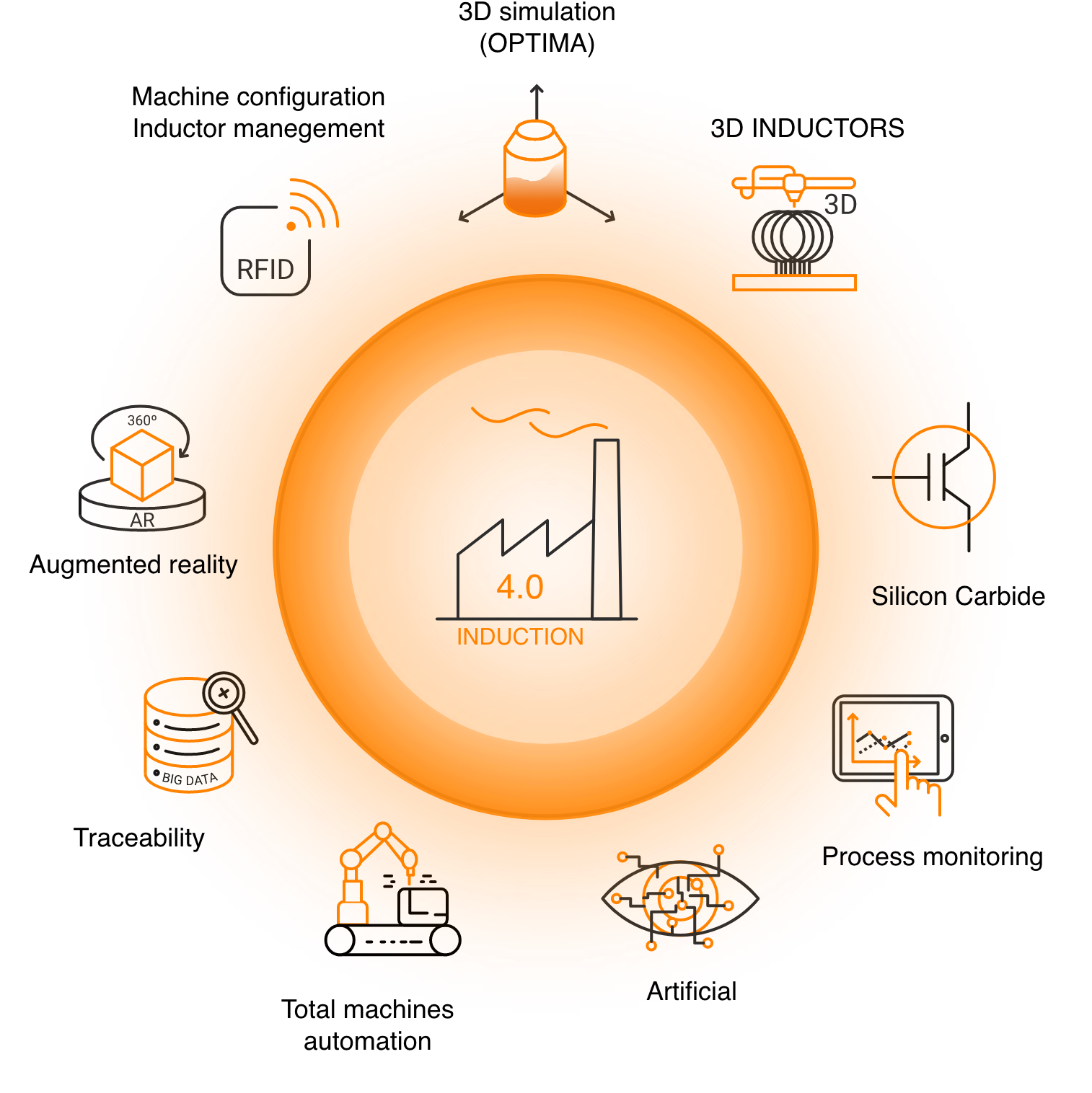

3D heating simulation

Optima Service

(OPTIMA)

3D INDUCTORS

3D Quenches

Silicon Carbide

(SiC)

Real-time Induction

Process Monitoring (IPM)

Artificial

vision

Full machine

automation (AIC)

Traceability

Process and systems data

OPC UA interface

Augmented reality

for assistance

(ConnectAR)

Machine configuration (Smart UI)

Inductor manegement

(Inductool)

You can simulate the induction process without the need for sample parts.

This reduces costs by anticipating the results and it saves time and resources that would otherwise be spent on engineering or laboratory hours.

Together with the 3D inductors you get the best process with the shortest possible lead time.

The 3D additive manufacturing era is here, and that applies to the induction world too. GH is the first induction heating group deploying hundreds of 3D printed coils since 2014.

Our induction experience and a field-proven and patented 3D printing coil technology (3DPCoil) based on EBM makes GH 3D inductors the safest investment.

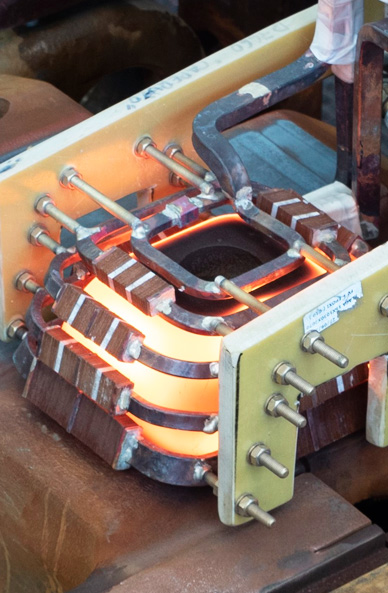

Our generators combine cutting edge technology with rugged construction for the ultimate in durability and versatility [5,400] kHz.

Our induction generators use state-of-the-art semiconductor materials to increase energy efficiency, high power density, bandwidth, and resistance to voltage and temperature.

Guarantee the quality of your production and comply with ISO/TS 16949 and CQI-9 standards thanks to the digital IPM system.

This represents a breakthrough in induction process monitoring.

It is based on 100% control over the treated parts; and real-time measurements of the parameters involved in the treatment.

GH will always adopt technologies that help optimize its machines in terms of design and investment, production, and operation.

Automated Inductor Changeover (AIC)

It is now possible to fully automate the machine and increase its availability and production.

With AIC, the inductors are changed without operator intervention.

This is possible thanks to the automated change of all inductor-machine interconnections: electrical, pneumatic, and cooling.

The OPC UA interface allows easy access to information through a standardised and easily programmable interface and enables the integration of traceability information into existing systems and applications.

The digitalisation and communication protocols of GH equipment and machines allow access to a large amount of data.

ConnectAR is a collaboration and communication platform to offer an augmented remote assistance service.

It improves productivity, reduces downtime, and makes technical problem identification easier by allowing instant live feedback in our video calls.

Intuitive interfaces are used to guide the operator and help reduce errors.

Our digital inductor traceability and analysis system allows you to optimize stock levels and predict possible improvements.

Because your goal is our goal

You will have available systems and methods that will improve your product and the profitability of your investment.

Our solidity is proven after more than 60 years in the market.

You will have an excellent service without continuity con problems.

We adapt 100% to your needs and specifications.

We define with you the project that best suits you.

You will be sure of the viability of your process before you invest thanks to specialists, simulations, and laboratory tests.

Systems and machines equipped with the latest technology designed to last as long as possible.

Silicon Carbide (SiC) power systems, inductors and machines developed to maximise efficiency.

We will be part of your team with our experience, creativity, and GH commitment to design the best solution for your case.

Services and solutions where you need them through our companies and technical service.

Experience

+60

Induction heating equipment installed in 50 countries

+5.000

Worldwide

360

Capacity

15.000

2025-10-22

Designed to provide a robust, efficient and economical solution without compromising on quality or reliability, this new model is an essential addition to any industry.

2025-03-20

The next edition of CoilTech Ausburg in Germany, on March 26 and 27, will be the ideal scenario for professionals and companies to learn first-hand about suppliers and innovations that enable competitiveness in their markets.

Induction 2025-01-29

Participating in "The Route to Fastener Innovation" and "Fastener Fair Global" reinforces our commitment to raising induction heating to excellence standards, benefiting our customers' manufacturing processes and final product quality.