Energy cable have revolutionized many facets of industry over the last couple of decades. It is an integral part of industry and ever present in our daily lives.

The production of energy cables requires continuous heat for preheating, curing and sealing of the insulation, annealing, coating and much more.

The compact size of induction combined with the need for closed loop temperature control and accuracy makes induction heating the ideal solution for this type of process.

GH Group offers a variety of innovative induction heating solutions within this sector, always focusing on the specific needs of each client.

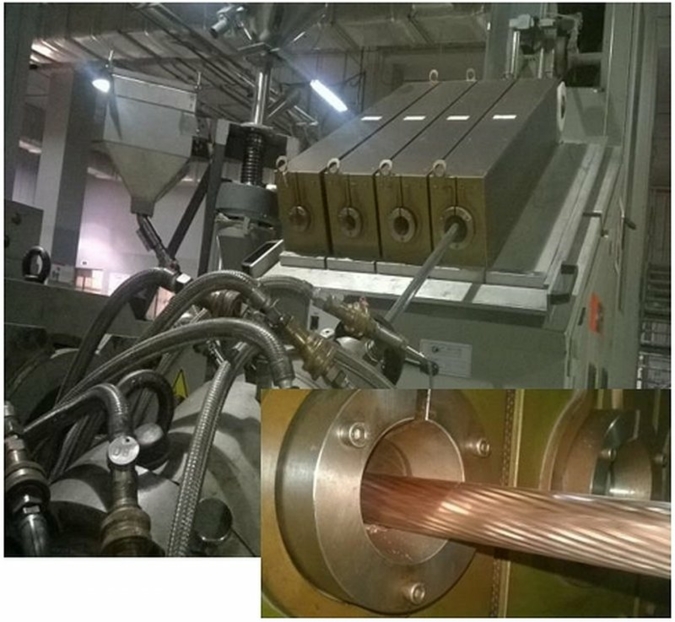

Inductive conductor preheater with automatic inductor change

The latest technology to prevent human errors in production and increase production reliability in CCV and CVC production lines for MF and HF cables.

GH Induction has developed a fully automated cable/conductor preheating system that avoids the risk of production losses due to human errors and greatly increases the production reliability. The automatic inductor change is the key, which also offers ergonomic advantages.

For more information, read the article of the specialized magazine Draht.