Induction solutions in automotive industry

Imagine we together create the solution that meets your needs 100%.

A safe investment

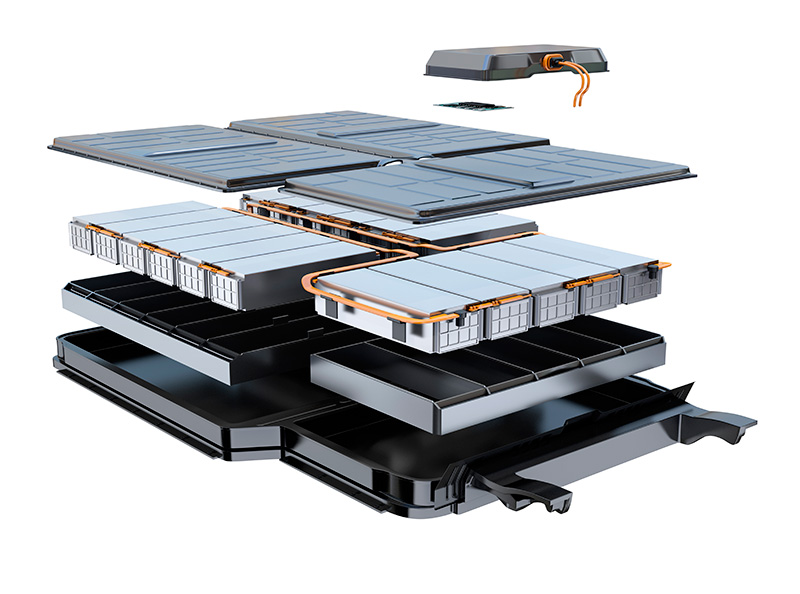

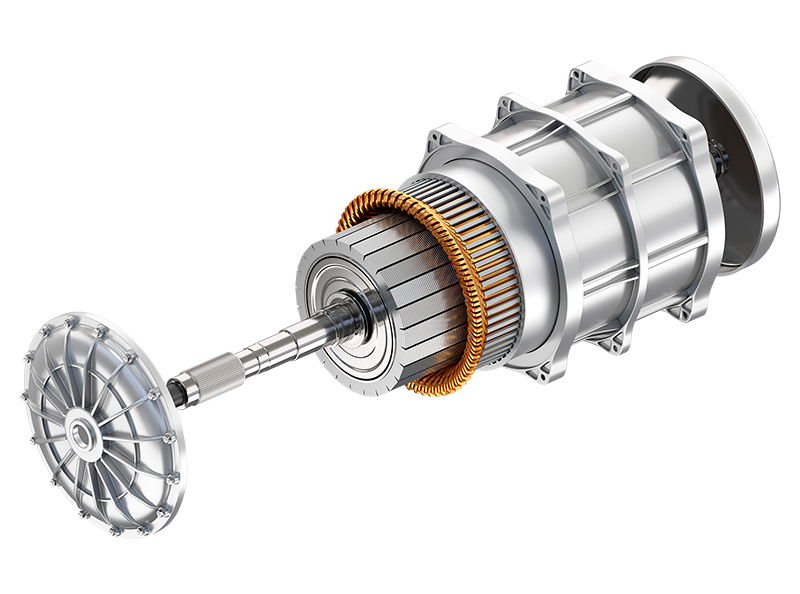

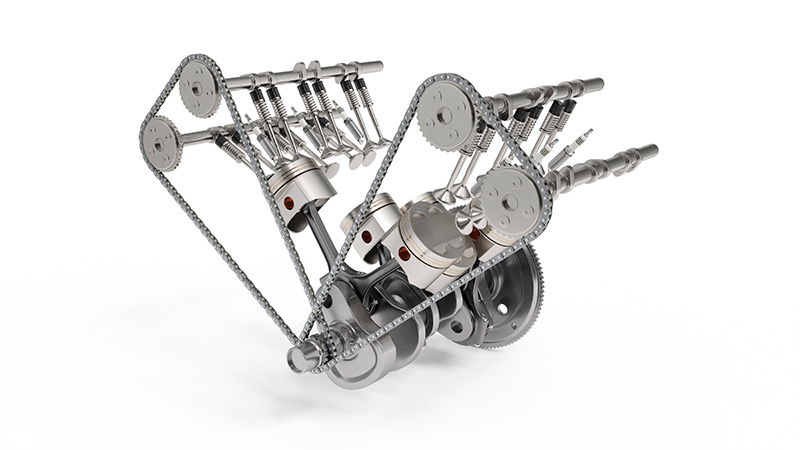

As the automotive industry evolves to meet the demands of the market with different technologies as ICEV (Internal Combustion Engine), EV (Electrical Vehicle) and Hybrids, supply chain pains have become more complex than ever before.

Whether you’re facing challenges related to fast adaptation, competitiveness, improving production efficiency, quality control, or sustainability, we understand your needs and working together we can help you.

At our company, we specialize in providing cost-effective and flexible turnkey solutions working together our customers. We incorporate the latest technology both own and others inside Industry 4.0 frame ensuring that you receive the ideal solution for your specific requirements. With over 60 years of experience we know what it takes to meet the high demands of the automotive industry.

GH Induction has become a pioneer and world market leader in this sector and supplies all premium OEMs with a wide offer:

Our induction heating technology can help you achieve precise heat treatment, such as hardening, tempering, and annealing, as well as effective induction joining methods like welding, brazing, shrink fitting, and bonding. Additionally, our general heating solutions can help with pre-heating, post-heating, curing, and straightening.

In summary, our innovation and global service can help you overcome the supply chain pains of the automotive industry. Together, we can find the ideal solution that meets your objectives.

Know more about our induction solutions in automotive industry

Quality and expenses reduction.

Additive manufacturing (AM) is the key to achieving full coil adaptation for your heated parts. With pure copper 3D inductors, the number of changeovers is reduced due to the extraordinary service life of the coils, up to 400% in certain applications.

Patented by GH.

Energy efficiency and ruggedness.

GH power supplies combine Silicon Carbide (SiC) cutting edge technology with rugged construction for the ultimate in durability and versatility [5,400] kHz. State-of-the-art Silicon Carbide (SiC) semiconductor materials are used to increase energy efficiency, high power density, bandwidth, and resistance to voltage and temperature.

Optimisation of investment and energy savings.

The rotating inductor is an innovative and unique system in which the inductor turns, and the workpiece is fixed. In this way, the machines are mechanically simplified in an extraordinary way, and the heating is more homogeneous. Thus, the investment is reduced, and the energy consumption is reduced.

Production quality and traceability.

IPM 4.0 (Induction Process Monitoring) is a mandatory digital control system to ensure the quality of the process that helps to comply with ISO/TS 16949 and CQI-9 standards. It is based on a 100% control of heated parts; and on real-time measurements of the involved parameters in the treatment.

ConnectAR is a remote assistance service. It improves productivity, reduces downtime, and makes technical problem identification easier by allowing instant live feedback in our video calls.

You get the best process with the shortest possible lead time. This service improves your heat treatment during your asset life combining 3D induction heating simulations and 3D printed inductors.