Induction heating machines

Imagine you take the best investment decision.

Imagine you meet your objective.

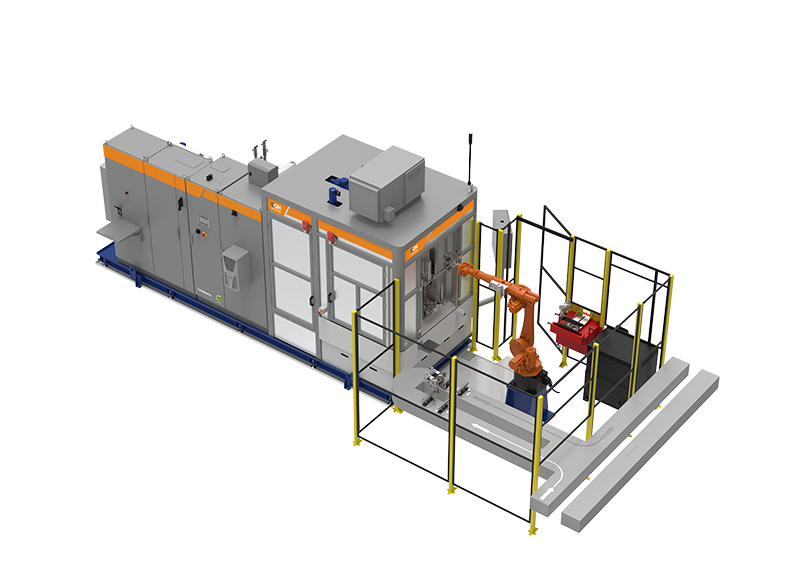

GH INDUCTION MACHINES

We understand that the decision to incorporate an induction machine into your production is an important one, both economically and technically.

That is why we guide you through the process to ensure your objectives are met:

100% adapted to your needs

GH designs and manufactures machines for any production volume, level of automation and Industry 4.0 functionality.

The parameters below are necessary to determine the characteristics of the installation, where we incorporate our technology and innovative systems to optimise the machine according to your priorities; adding value to this asset.

Required parameters from customer:

Different designs:

IGBT, SiC

Single and Multioutput:

For low and medium production volume.

The TVK family consists of compact and versatile vertical machines with minimal factory layout, plug & play commissioning, and upgradable functionalities.

All components are housed in a single aluminum structure, which minimises the interconnections and ensures total accessibility for operation and maintenance.

Different models according to:

Reference Models: TVK-S1000, TVK-M800, TVK-SD400

In addition to 100% customised machines with completely new designs, we offer proven basic installations for different applications such as forging, heat treatment, heat staking, high vacuum heating.