Induction solutions for heavy machinery and trucks

Imagine you improve your production efficiency.

Imagine shortening reference changes with full automation.

In this type of machinery, there is a wide variety of parts to be treated with different production requirements, such as engine block components, undercarriage components, gears, bushings, pins, gears, and plow blades.

We adapt to your production by designing robust, versatile, and high precision heat treatment solutions capable of handling heavy parts. They can cover different production volumes and levels of automation, always with 100% part traceability thanks to IPM 4.0.

Our innovative AIC (Automatic Inductor Change) system drastically reduces reference changes and human error, maximising productivity and accelerating the return on investment in induction equipment. Contact us to see if you can benefit from the AIC system.

On the other hand, the lifetime of the equipment is guaranteed by our global service.

Reference projects

Heat treatment of track shoe part with Automated Inductor Change (AIC)

Designed to increase the manufacturer’s production by reducing the cycle time of 1Tn parts with multiple treatment zones and with quality traceability of each treatment per shoe.

The solution is based on a machine with robust mechanics for the hardening of heavy part with fully automated both in the handling of the parts and in the changing of the inductors which reduces drastically the manual inductor changeovers. The Automated Inductor Change (AIC) is exclusive to GH and the level of automation is configurable.

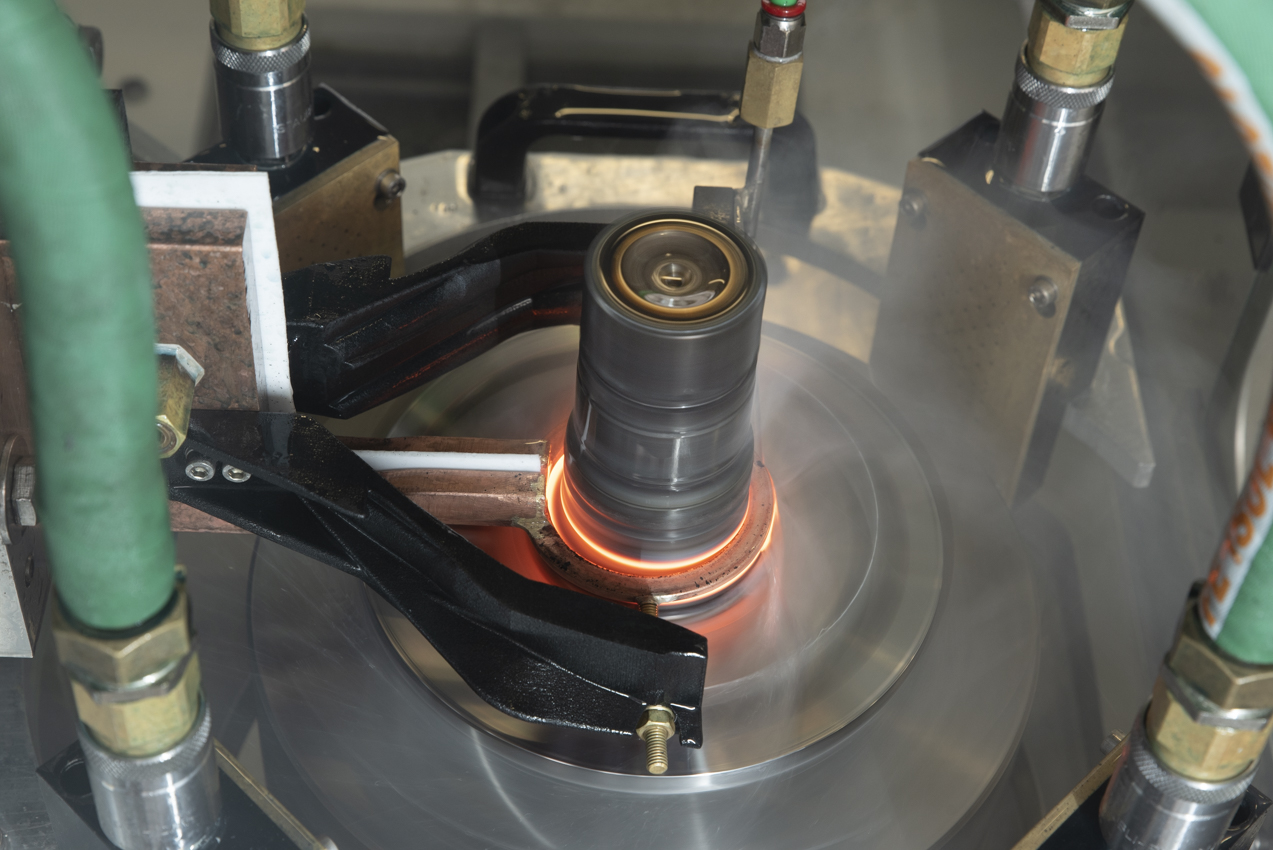

Hardening machine of an outer shaft for heavy machines

Solutions based on robust machines designed for the treated parts to ensure their operation in harsh conditions. Our low-maintenance machines offer long-term reliability, ensuring consistent performance over time.

Each processed part is meticulously tracked to meet the manufacturer’s production requirements. Enhance your manufacturing processes with our innovative technology designed for reliability and long service life.

Increase of productive efficiency, no manual changeovers.

Recommended when manual changeovers are high time-consuming and could imply important stoppages due to human mistakes. Depending on your production requirements and your investment, GH designs and customizes the solution.

Production quality and traceability are two of the most important aspects of any manufacturing process. As such, IPM (Induction Process Monitoring) is a mandatory digital system to ensure the quality of the process, comply with ISO/TS 16949 and CQI-9 standards. It is based on a 100% control over the treated parts; and on real-time measurements of the parameters involved in the treatment.

ConnectAR is a remote assistance service. It improves productivity, reduces downtime, and makes technical problem identification easier by allowing instant live feedback in our video calls.