Induction solutions for metal tools

Imagine you improve your productive efficiency and product quality.

Induction heating for metal tools

Induction heating is a highly efficient technology that offers several advantages in the production of metal tools. It is fast, precise, clean, safe, and energy efficient. These advantages make this process ideal for tool manufacturing for hand tools, power tools or tool holders.

GH Induction solutions make possible to produce high-quality and high-performance tools. Depending on the application and your requirements, they can cover different levels of production and automation always with part traceability (IPM 4.0). Our innovative AIC system for automated inductor changes allows a drastic reduction changeovers and human mistakes shortening the investment on the induction equipment.

Typical applications go from forging up to the heat treatment or brazing depending on the tool. We can develop new applications and processes using our know-how, 3D heating simulations and our laboratory.

The long-life service of the equipment is guaranteed by our global service.

Know more about our induction solutions for metal tools

Automated plier hardening and tempering

Lean induction systems and machines with different configurations depending on production needs. From low to very-high production volumes and requirements.

Different tools and references as pliers, screwdrivers, chisels, wrenches, drill bits, hammers, shovels, garden tools can be heated for precision hardening, tempering, curing, forging or any other joining applications (heat staking, bonding, brazing).

Precision hardening of screws

High precision induction hardening machines for lean manufacturing. Wide range of metrics M8-M16 and short cycle times, up to 180 parts per minute. Different parts as trilobular screws for automotive, fasteners for concrete and construction.

High energy efficient hardening machines for very large screws.

Induction heating systems for hot heading and thread rolling; surface coatings and powder curing.

Hardening and tempering of a tool holder with five treatment areas each part and AIC system

Productivity-enhancing solutions for hardening and tempering of tool holders with automated inductor changeover that maximizes the machine output.

A tool holder part has different treatment areas, and the production batches are short. GH Automated Inductor Change (AIC) system reduces drastically the manual inductor changeovers which are needed increasing the productivity and facilitating the automation.

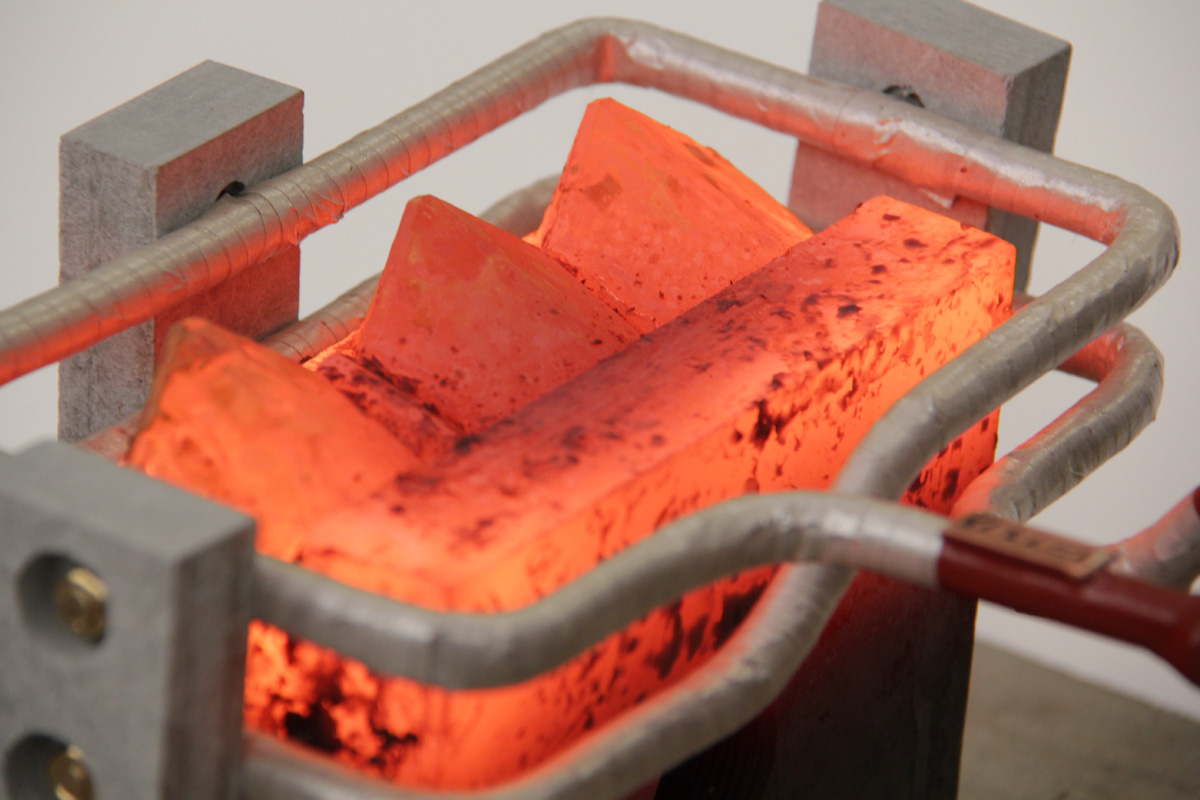

Brazing of carbide inserts using a high energy efficient induction system

Efficient and versatile brazing systems for carbide inserts or widias used in various industries such as metalworking, woodworking, and mining. This solution is preferred over traditional methods like furnace brazing as it offers several benefits such as precise heating, fast cycle times, control, and reduced energy consumption. One key component is GH power supplies with a wide range of frequencies.

Increase of productive efficiency, no manual changeovers.

Recommended when manual changeovers are high time-consuming and could imply important stoppages due to human mistakes. Depending on your production requirements and your investment, GH designs and customizes the solution.

Quality and expenses reduction.

Additive manufacturing (AM) is the key to achieving full coil adaptation for your heated parts. With pure copper 3D inductors, the number of changeovers is reduced due to the extraordinary service life of the coils, up to 400% in certain applications.

Patented by GH.

Energy efficiency and ruggedness. GH power supplies combine Silicon Carbide (SiC) cutting edge technology with rugged construction for the ultimate in durability and versatility [5,400] kHz.

State-of-the-art Silicon Carbide (SiC) semiconductor materials are used to increase energy efficiency, high power density, bandwidth, and resistance to voltage and temperature.

You get the best process with the shortest possible lead time. This service improves your heat treatment during your asset life combining 3D induction heating simulations and 3D printed inductors.

Production quality and traceability are two of the most important aspects of any manufacturing process. As such, IPM (Induction Process Monitoring) is a mandatory digital system to ensure the quality of the process, comply with ISO/TS 16949 and CQI-9 standards. It is based on a 100% control over the treated parts; and on real-time measurements of the parameters involved in the treatment.

ConnectAR is a remote assistance service. It improves productivity, reduces downtime, and makes technical problem identification easier by allowing instant live feedback in our video calls.