NEW! Automatic inductor change in cable preheating

GH Induction has launched the first system of inductive conductor preheater with automatic inductor change.

GH Induction has launched the first system of inductive conductor preheater with automatic inductor change.

It is the latest technology to prevent human errors in production and increase production reliability in CCV and CVC production lines for MF and HF cables.

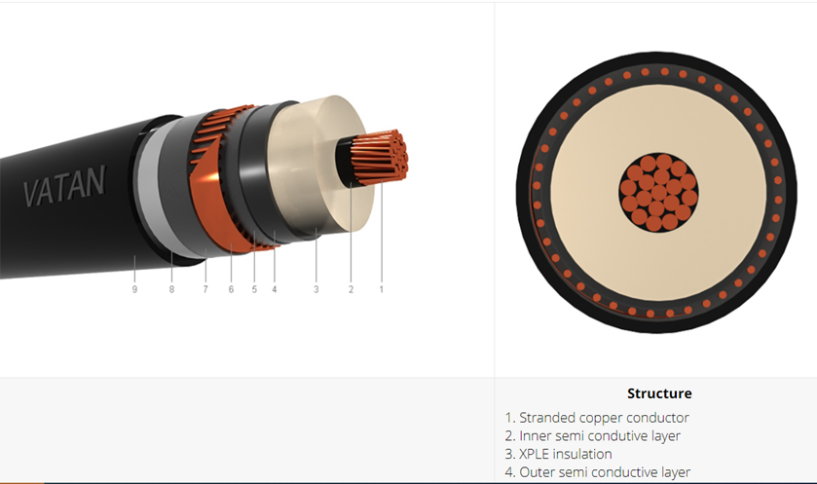

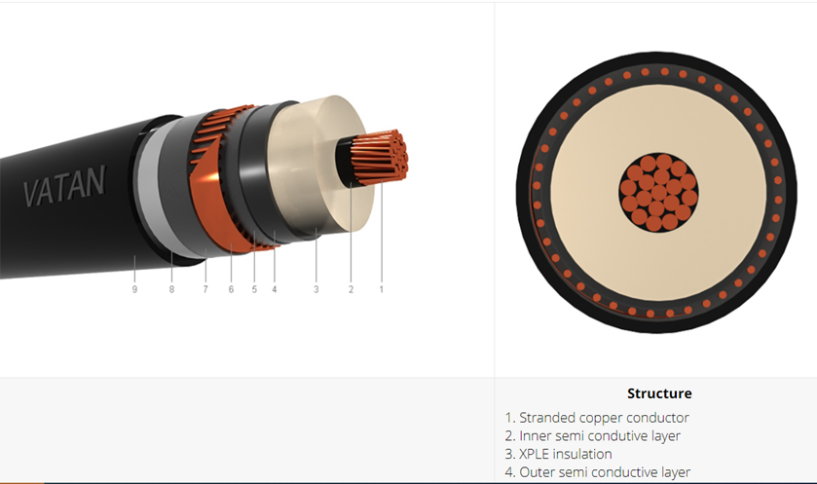

Inductive preheating of conductors is used for applying insulation layers (extrusion) to achieve high quality insulation at high production speeds.

Why is inductive heating so important in this process?

In order to apply the cross-linked polyethylene (XLPE, XLPE) insulation, it is extremely important to cure it homogeneously. There may be gaps in the material which may lead to insulation breakdown due to the high voltage flowing through the cable.

This layer is relatively thick, so it is difficult to cure the insulation only from the outside. In this case, it would be necessary to run the cable through a long heater at a very slow speed to cure the material. However, if the conductor is heated before the insulation layer is applied, the insulation material is also indirectly heated from the inside by the heat given off by the conductor. With induction heating, it is therefore possible to apply a homogeneously cured insulation layer at a high production rates.

You can read a complete article in the specialized wire and cable magazine, Draht (in German).

Induction heating is a gentle, non-contact and environmentally friendly solution. This process has become widely accepted for heating conductors and is ideal for many different tasks in the manufacturing of wire and cable products.

Since the heat is generated directly in the cable without contact, the cable surface remains perfectly smooth and scratch-free. The insulation and jacketing processes of high and medium voltage cables, submarine cables, mining cables and other power cable applications are a perfect example of processes where induction heating offers exceptional benefits.